PriceList for Pe Fiber Ripstop Fabric - Anti-cutting and wear-tear fabric – Huidun

PriceList for Pe Fiber Ripstop Fabric - Anti-cutting and wear-tear fabric – Huidun Detail:

Bulproof material

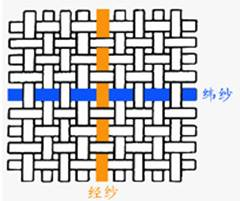

Ultra high molecular weight polyethylene fiber after woven machine processing, made into special anti-cutting, wear and tear fabric, can also be processed through coating, make special composite materials, used for material reinforcement, structural reinforcement and industrial cloth.

Ultra-high molecular weight polyethylene fibers have high energy absorption characteristics, and can be used not only in the bulletproof field, but also in anti-cutting, stabbing prevention, and impact-resistant composites.Machine fabrics and knitwear of ultra-high molecular weight polyethylene fibers play good protective roles in anti-cutting gloves, fencing suits, protective clothing, and minesweeper clothing.At the same time, its excellent wear resistance, chemical corrosion resistance and hydrophobic properties, to ensure the high durability in the process of use.

In high-performance fibers, ultra-high molecular weight polyethylene fibers can quickly absorb impact energy, avoid the brittle cracking of fiberglass or carbon fiber, and greatly reduce the weight of the product.

Acupuncture non-woven fabric made of ultra-high molecular weight polyethylene fiber has high strength, chemical corrosion resistance, tear resistance, wear resistance, breathable, environmental protection, light quality and other excellent performance, and can be widely used in medical and health care, industry, agriculture, clothing and other fields.

Product characteristics

High specific strength, high specific modulus. The specific strength is more than ten times that of the same section wire, second only to the specific modulus.

Low fiber density and can float.

Low fracture elongation and large fault power, which has a strong energy absorption ability, and thus has an outstanding impact resistance and cutting resistance.

Anti-UV radiation, neutron-proof and γ -ray prevention, higher than energy absorption, low permittivity, high electromagnetic wave transmission rate, and good insulating performance.

Chemical corrosion resistance, wear resistance, and long deflection life.

Physical Performance

☆ Density: 0.97g/cm3. Lower density than water and can float on the water.

☆ Strength: 2.8~4N/tex.

☆ Initial modulus: 1300~1400cN/dtex.

☆ Frault elongation: ≤ 3.0%.

☆ Extensive cold heat resistance: certain mechanical strength under-60 C, repeated temperature resistance of 80-100 C, temperature difference, and the use quality remains unchanged.

☆ The impact absorption energy is nearly twice the high of counteraramide fiber, with good wear resistance and small friction coefficient, but the melting point under stress is only145~160℃。

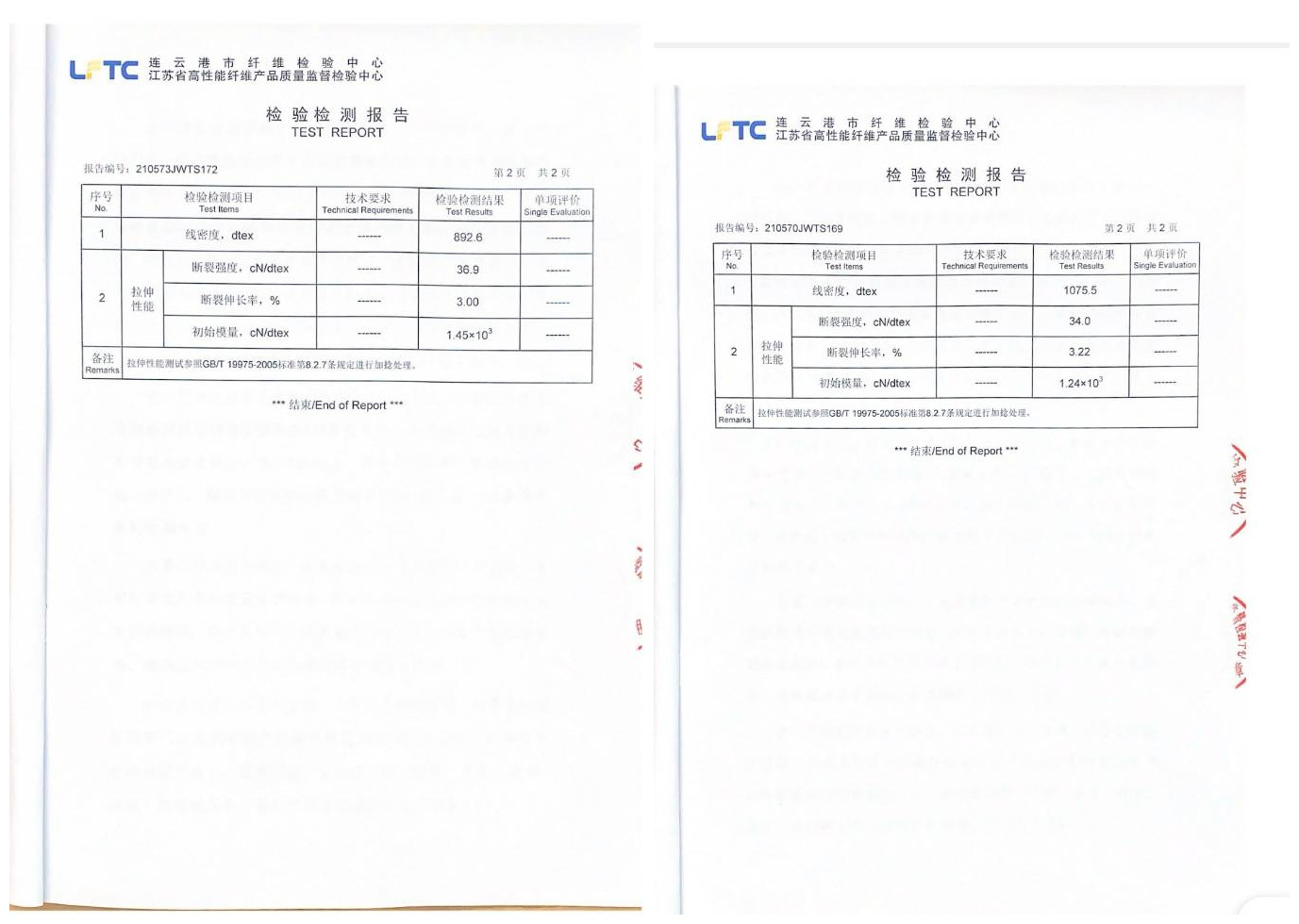

Spec:800D-1200D

|

Item |

Count dtex |

Strength Cn/dtex |

Modulus Cn/dtex |

Elongation% |

|

|

HDPE |

800D |

885 |

38 |

1812 |

2.81 |

|

|

1000D |

1093 |

32.5 |

1492.11 |

2.39 |

|

|

1200D |

1318 |

31.6 |

14385.39 |

2.68 |

Test Report

Product detail pictures:

Related Product Guide:

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for PriceList for Pe Fiber Ripstop Fabric - Anti-cutting and wear-tear fabric – Huidun , The product will supply to all over the world, such as: Czech, Amman, Cologne, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!