functional knitting beauty clothing aspect as the application of spandex knitted fabrics, its function has also been gradually developed plastic body, through to embed the spandex knitted fabric, can form the plastic body type of knitted garments, and can have carry buttock, belly in effect, and on the current clothing market occupies a large proportion of sales. At the same time, spandex has the defensive effect of thrombus, which also makes knitted socks containing spandex popular. It is through the adjustment of spandex input, the elastic compression force is gradually increased from the upper end of the knitted socks to the lower end, so as to further improve the limb blood flow, so as to achieve the functional effect of preventing thrombus.

The difference between European standard EN388 and American standard ANSI/ISEA105

In these two standards, the expression of the level of cut resistance is different。

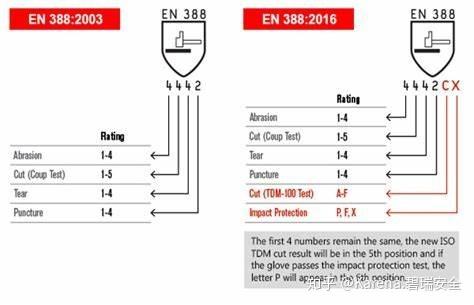

The cut-resistant gloves certified by the European standard will have a shield graphic with the words “EN 388″ on it. There are 4 or 6 numbers and letters under the shield graphic. If it is 6 digits and letters, it means that the latest EN 388:2016 standard is used. If it is 4 digits, it means that it is the old 2003 standard.

↑ The picture on the left is the old standard, and the picture on the right is the new standard.

The first 4 digits have the same meaning, which are “wear resistance”, “cut resistance”, “tear resistance”, and “puncture resistance”. The larger the number, the better the performance. The fifth letter also means “cut resistance”, but the test method is different from that of the second digit, and the representation of the cut resistance grade is also different, which will be discussed in detail later. The sixth letter stands for “impact resistance” and is also represented by letters. However, there will be a sixth digit only if the impact resistance test is carried out. If it is not carried out, there will only be 5 digits. Although the 2016 version of the European standard has been used for more than 4 years, there are still many older versions of gloves on the market. The cut-resistant gloves certified by the new and old standards are all qualified gloves, but it is more recommended to buy cut-resistant gloves that use 6-digit numbers and letters to indicate the performance of the gloves. American standard ANSI 105 expression.

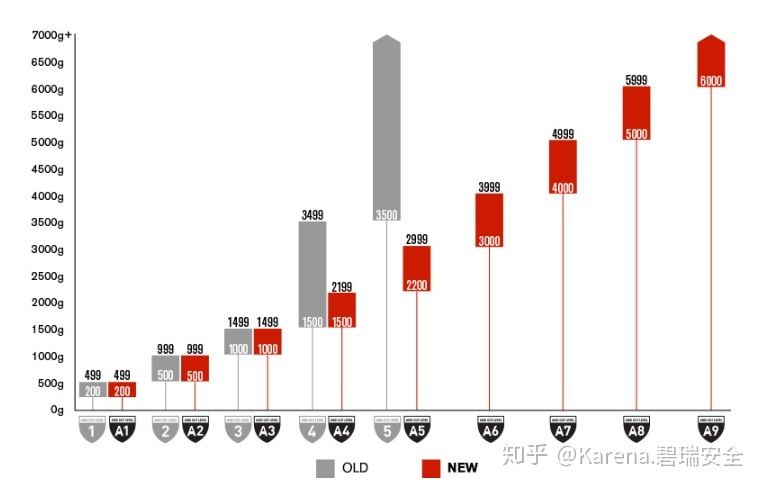

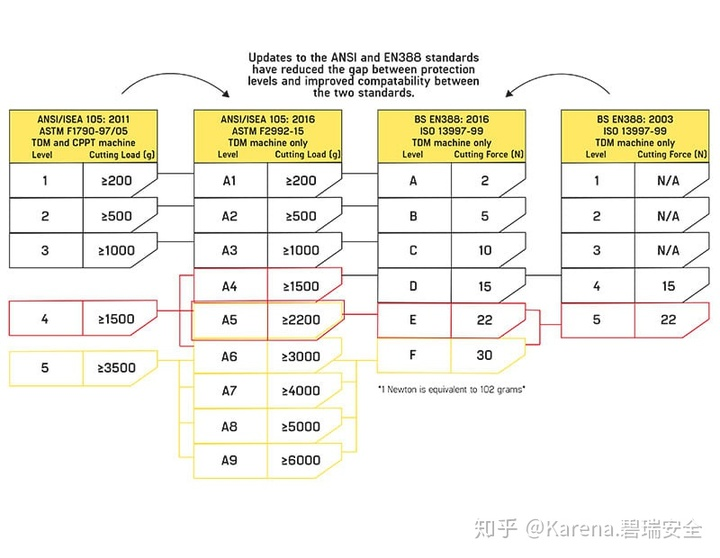

In 2016, the American standard ANSI 105 has also undergone an update. The original cut resistance level was represented by 1-5 in the shield graphic, and now it is represented by “A1″ to “A9″. Similarly, the larger the number, the higher the level of cut resistance.

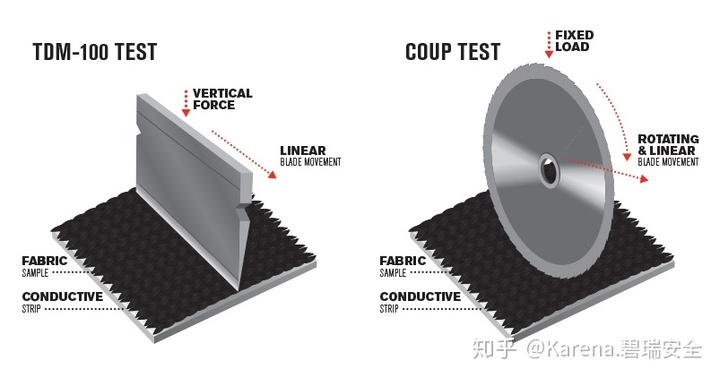

But why update the classification method from 5 levels to 9 levels? The reason is that with the emergence of more new materials, a detailed classification is required to indicate the cut resistance of gloves. In the new grading method, A1-A3 is basically the same as the original 1-3, but compared with the original 4-5, A4-A9 uses 6 grades to divide the original 2 grade range, which can be resistant to gloves. Cut the sex for a finer graded expression. In the ANSI standard, the update is not only the expression of the level, but also the test method. The original test used ASTM F1790-05 standard, which allows testing on TDM-100 machine (test method is called TDM TEST) or CPPT machine (test method is called COUP TEST), now ASTM F2992-15 standard is used, only TDM is allowed TEST to test. What is the difference between TDM TEST and COUP TEST?

COUP TEST uses a circular blade with a pressure of 5 Newtons to roll and cut on the glove material, while TDM TEST uses a blade to press on the glove material with different pressures, cutting back and forth horizontally at a speed of 2.5 mm/s. Although the new European standard EN 388 stipulates that two test methods, COUP TEST and TDM TEST, can be used, under COUP TEST, if it is a high-performance anti-cutting material, the round blade may become blunt. It is calculated that the blade becomes blunt, and TDM TEST is mandatory. It should be noted that if this high-performance anti-cutting glove has undergone TDM TEST, an “X” can be written on the second digit of the certification graphic. At this time, the cut resistance is only represented by the fifth letter. If it is not a high-performance cut-resistant glove, it is unlikely that the glove material will dull the COUP TEST blade. At this time, TDM TEST can be omitted. The fifth digit of the certification pattern is indicated by an “X”.

↑ Non-high-performance anti-cutting glove material, no TDM TEST, and no impact resistance test.

↑ High-performance cut-resistant glove material, TDM TEST has been carried out, COUP TEST and impact resistance tests have not been carried out.

| New American Standard ANSI/ISEA 105:20 | New European Standard EN 388:2016 | ||

| Test Methods | TDM | TDM | Coup Test |

| Test classification | A1-A9 | A-F(5th place) | 1-5(second) |

| Is the standard mandatory | Voluntary standards | Mandatory standards | |

Correspondence between American and European standards.

American standard A1-A3 and European standard AC belong to low cut protection level, American standard A4-A5 and European standard E belong to medium cutting protection grade, American standard A6-A9 and European standard F belong to higher cutting protection grade .

Post time: Aug-20-2021