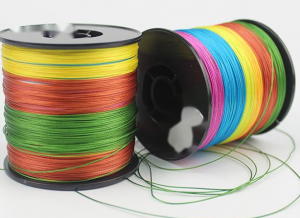

Ultra high molecular weight polyethylene cold-feeling fabric

Short Description

(1) With a high thermal conductivity.Make the heat of the human skin surface through the mat surface material more quickly and lasting spread to a wide area.

(2) has a higher thermal capacity.When the mat with relatively high temperature is relatively low temperature, the unit quality mat can absorb more human body heat, the human body can feel obvious touch temperature difference, so as to obtain cool feeling.

(3) Easy to fold and light density.Easy carrying and storage and small space.

Ultra high molecular weight polyethylene fiber has a linear molecular chain arrangement characteristics, with a unique cool feeling effect, has been applied in bedding and special fabrics, to provide a more comfortable experience for living and wear.

|

Item |

Count dtex |

Strength Cn/dtex |

Modulus Cn/dtex |

Elongation% |

|

|

HDPE |

50D |

55 |

31.98 |

1411.82 |

2,79 |

|

100D |

108 |

31.62 |

1401.15 |

2.55 |

|

|

200D |

221 |

31.53 |

1372.19 |

2.63 |

|

|

400D |

440 |

29.21 |

1278.68 |

2.82 |

|

|

600D |

656 |

31.26 |

1355.19 |

2.73 |

Product characteristics

High specific strength, high specific modulus. The specific strength is more than ten times that of the same section wire, second only to the specific modulus.

Low fiber density and can float.

Low fracture elongation and large fault power, which has a strong energy absorption ability, and thus has an outstanding impact resistance and cutting resistance.

Anti-UV radiation, neutron-proof and γ -ray prevention, higher than energy absorption, low permittivity, high electromagnetic wave transmission rate, and good insulating performance.

Chemical corrosion resistance, wear resistance, and long deflection life.

Physical Performance

☆ Density: 0.97g/cm3. Lower density than water and can float on the water.

☆ Strength: 2.8~4N/tex.

☆ Initial modulus: 1300~1400cN/dtex.

☆ Frault elongation: ≤ 3.0%.

☆ Extensive cold heat resistance: certain mechanical strength under-60 C, repeated temperature resistance of 80-100 C, temperature difference, and the use quality remains unchanged.

☆ The impact absorption energy is nearly twice the high of counteraramide fiber, with good wear resistance and small friction coefficient, but the melting point under stress is only145~160℃。